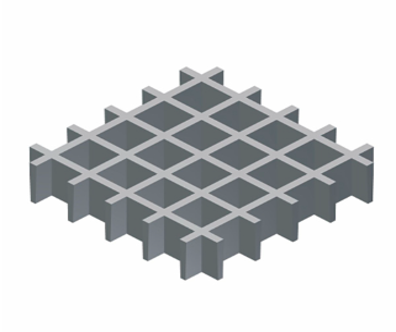

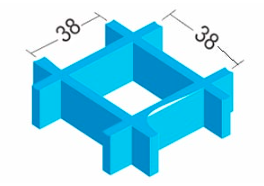

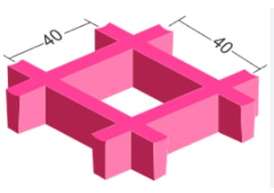

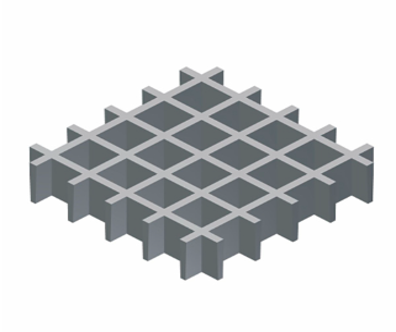

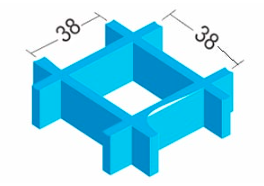

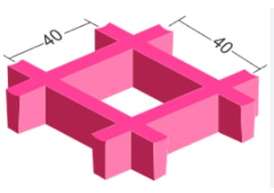

- Mesh Size :38x38 mm , 40x40 mm , 50x50 mm

- Height :38mm,40mm,50 mm

- Sheet Size 1220x3660 mm ( Standard ) & Customized is also available

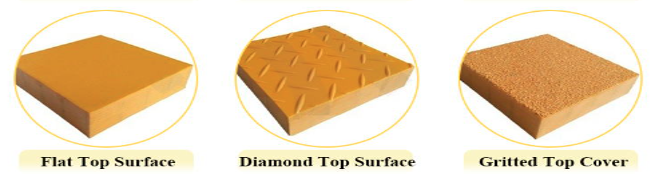

- Surface :Concave , Smooth , Gritted , Covered

Note : Customized size & Colour is also available upon the request

Note : Customized size & Colour is also available upon the request