- Pre-Galvanized:Pre-galvanized steel is coated with a layer of zinc before it's formed into the final product. This protective layer provides moderate corrosion resistance and is often used for indoor applications.

- Hot Dip Galvanized:Hot dip galvanizing involves immersing steel in molten zinc, creating a thick, durable coating that offers excellent corrosion protection. It's commonly used for outdoor and industrial applications.

- Stainless Steel:Stainless steel is a corrosion-resistant alloy that doesn't require additional coatings. It's known for its strength and resistance to rust, making it ideal for environments with high moisture or chemical exposure

- PU Paint:PU (Polyurethane) paint is a type of durable coating applied to surfaces to enhance their appearance and protect them from wear, weather, and UV exposure. It's commonly used for automotive and furniture applications.

- Powder Coated:Powder coating is a method of applying a dry powder to a surface, which is then cured with heat to create a tough, protective layer. It's known for its durability, vibrant color options, and resistance to chipping and fading, making it suitable for a wide range of products, including metal furniture and automotive parts

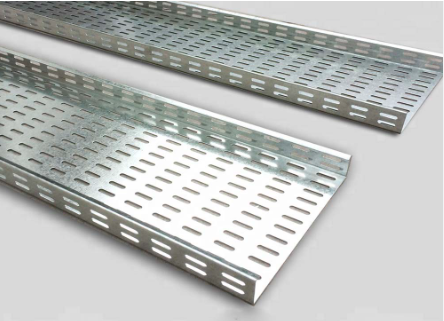

Galvanized Cable Tray

- Home

- Galvanized Cable Tray

Galvanized Cable Tray

At “Altra Universe “ we are dedicated to providing top-quality galvanized cable trays to meet all your cable management needs. With a commitment to excellence and customer satisfaction, we have become a trusted supplier in the industry. Whether you require pre-galvanized, hot-dip galvanized, or specialized cable trays, we've got you covered

Finish Available

Technical Details

- Width(W) :50 mm to 1000 mm

- Height (H) :25 mm to 100 mm

- Thickness (t)1.6 to 3 mm

- Length (L) :2500/3000 mm

- Finish :Pre-Galvanized , Hot dip Galvanized , Powder coated , PU Paint , Stainless Steel

Note :- Customized Size is also available as per customer request

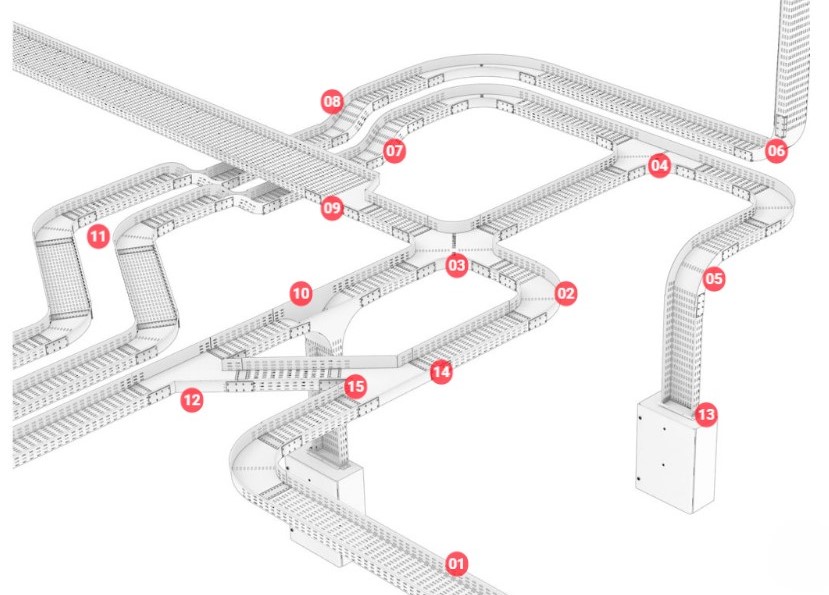

Perforated Cable Tray Accessories

- Straight Section

- 90° Horizontal Bend

- Horizontal Cross

- Horizontal EQUAL Tee

- 90° External Riser

- 90° Internal Riser

- 45° External Riser

- 45° Internal Riser

- Right Hand Reducer

- Vertical Tee

- 60° Horizontal Bend

- WYE Branch

- Box Connector

- Standard Connector

- Fish Plate Connector

Industries in we serve:-

- Manufacturing

- Banking

- Hospitality

- Oil and Gas

- Infrastructure & Transportation

- IT Insfrastructure

- Aerospace

- Building & Construction

- Public sector

- Renewable energy

Technical Details

- Width(W) :150 mm to 1200 mm

- Height (H) :50 mm to 200 mm

- Thickness (t)1.6 to 3 mm

- Length (L) :2500/3000 mm

- Finish :Pre-Galvanized , Hot dip Galvanized , Powder coated , PU Paint , Stainless Steel

Note :- Customized Size is also available as per customer request

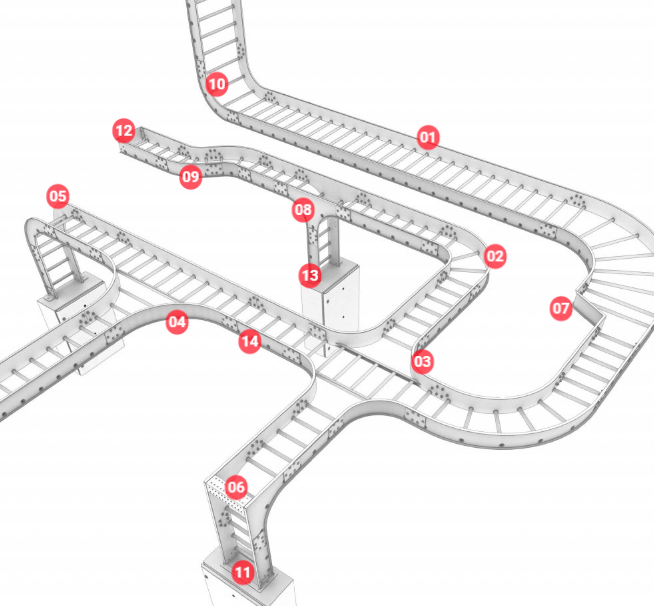

Ladder Cable Tray & Accessories

- Straight Section

- 90° Horizontal Bend

- Horizontal Cross

- Horizontal EQUAL Tee

- 90° External Riser

- 90° Vertical Support Bend

- Left Hand Reducer

- Vertical Tee

- 45° Horizontal Bend

- 90° Internal Riser

- Box Connector

- Stop End

- Right Angle Connector

- Standard Connector

Major Industries in we serve:-

- Manufacturing Plant

- Refainieries

- Telecomminication

- Infrastructure & Transportation

- IT Insfrastructure

- Aerospace

- Building & Construction

- Public sector

- Renewable energy

Technical Details

- Width(W) :50 mm to 600 mm

- Height (H) :25 mm to 200 mm

- Thickness (t)1.2 to 3 mm

- Length (L) :2500/3000 mm

- Finish :Pre-Galvanized , Hot dip Galvanized , Powder coated , PU Paint , Stainless Steel

Note :- Customized Size is also available as per customer request

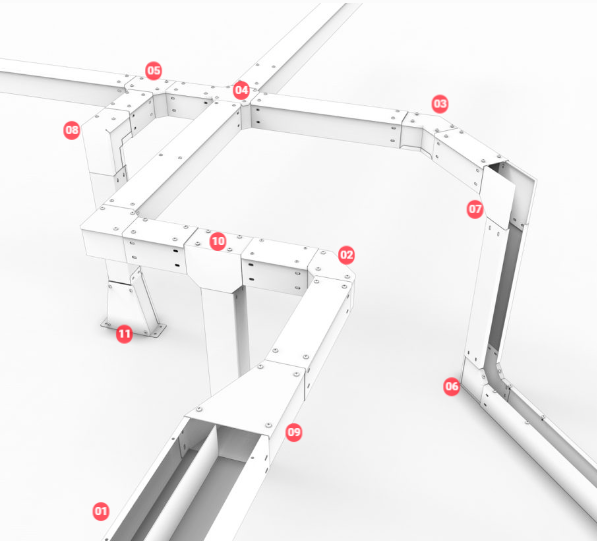

Raceway/Trunking cable tray & Accessories

- Straight Section

- 90° Horizontal Bend

- 45° Horizontal Bend

- Horizontal Cross

- TEE

- 90° External Riser

- 90° Internal Riser

- 90° Internal Riser

- Right Hand Reducer

- Vertical Tee

- Bell Mount

Application Area :-

- Industrial Environment

- Residential

- Commercial space

- Data center

- Healthcare Facility