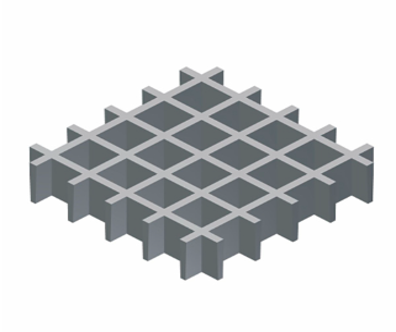

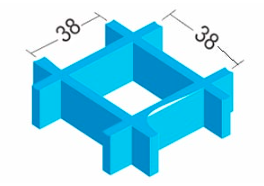

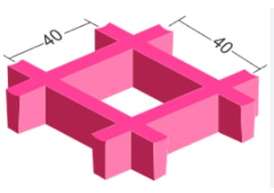

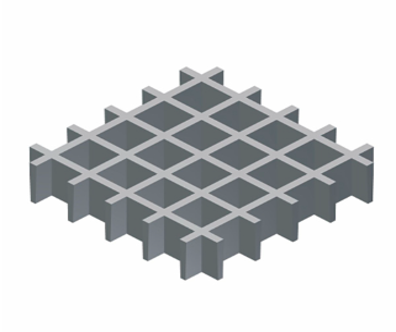

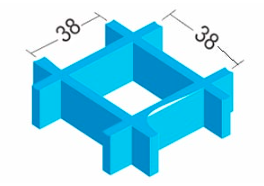

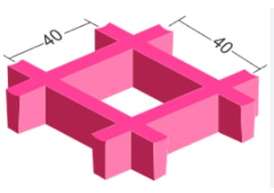

- Mesh Size :38x38 mm , 40x40 mm , 50x50 mm

- Height :38mm,40mm,50 mm

- Sheet Size 1220x3660 mm ( Standard ) & Customized is also available

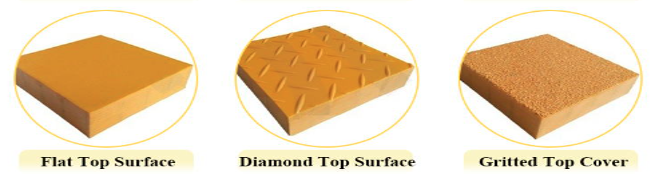

- Surface :Concave , Smooth , Gritted , Covered

Note : Customized size & Colour is also available upon the request

At “ALTRA UNIVERSE”, we are your trusted source for top-quality FRP grating solutions. With a commitment to excellence and innovation, we specialize in manufacturing and supplying a wide range of FRP grating products to meet the diverse needs of various industries.

FRP Grating, or Fiberglass Reinforced Plastic Grating, is a type of grating made from composite materials known as fiberglass reinforced plastic. It is used in a variety of applications where traditional metal grating may not be suitable due to factors like corrosion resistance, lightweight requirements, or electrical insulation properties. Here is a definition and description of FRP grating

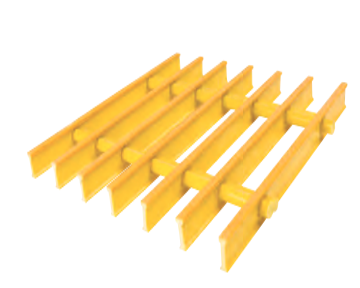

FRP Grating is a structural flooring material composed of a matrix of fiberglass reinforcement and a polymer resin binder. It is manufactured through a pultrusion process, where continuous glass fibers are saturated with resin and then cured to form rigid grating panels. The resulting product is durable, corrosion-resistant, and possesses various mechanical properties suitable for a wide range of industrial and commercial uses.

| Description | FRP/GRP Grating | Hot Dip Galvanised | Stainless Steel |

|---|---|---|---|

| Strength to weight ratio | Excellent | Average | Average |

| Life span | Excellent | Good | Very Good |

| Life Cycle Cost effectiveness | Excellent | Good | Good |

| Chemical Resistivity | Excellent | Good | Excellent |

| Electrical Non-conductivity | Excellent | Poor | Poor |

| Rust proof Features | Excellent | Average | Excellent |

| Handling | Very easy | Difficult | Difficult |

| Installation cost | Very low | High | High |

| Anti skid | Available | Not Available | Not Available |

| Colour selection | Available | Not Available | Not Available |

Note : Customized size & Colour is also available upon the request

Note : Customized size & Colour is also available upon the request

| Characteristic | Molded Grating | Pultruded Grating |

|---|---|---|

| Manufacturing Process | Molding process with a closed mold | Pultrusion process with a die |

| Raw Materials | Resin (e.g., polyester, vinyl ester, phenolic) mixed with fiberglass rovings | Resin (e.g., polyester, vinyl ester, phenolic) impregnated onto continuous fiberglass rovings pulled through a die |

| Strength | High strength-to-weight ratio | Exceptionally high strength |

| Corrosion Resistance | Corrosion-resistant but lower than pultruded | Highly corrosion-resistant |

| Weight | Lightweight | Lightweight |

| Electrical Conductivity | Non-conductive | Non-conductive |

| Chemical Resistance | Resistant to chemicals | Highly resistant to chemicals |

| Surface Options | Textured, slip-resistant surfaces available | Various surface options, including textured |

| Customization | Can be customized | Can be customized |

| Typical Applications | Industrial flooring, walkways, platforms, water treatment | Structural support, heavy-duty applications, corrosive environments |

| Maintenance | Low maintenance | Low maintenance |

| Cost | Generally lower cost | Higher cost than molded grating |